There is a misconception among pen collectors regarding the claim that certain aftermarket pen parts were made on original Parker machinery. While the claim might be narrowly true, the use of an ex-Parker buffing wheel or drill press isn't what is called to mind. Rather, the implication is that the aftermarket parts were made in exactly the same way as the originals and to the exact same specifications. If we are talking about plastic parts, this they were not.

These parts were machined, not molded. Parker made them using automatic screw machines, which were large and very expensive programmable analog machine tools that could be configured to produce all sorts of parts. The size and cost (even used) of such machines made them utterly impractical for a small shop, along with the difficulty and expense of setting them up. They were only suitable for large-scale mass production, and nowadays have been almost entirely replaced by digitally-controlled CNC machine tools. Even if one were to gain access to an ex-Parker screw machine, it wouldn't be any different from one that had been used to make bicycle or clock parts. The machine itself wasn't what made the parts so much as its programming.

A blog about antique and vintage writing instruments: fountain pens, mechanical (propelling) pencils, dip pens, and more.

Sunday, October 22, 2023

Unpacking "made on original Parker machinery"

Friday, August 4, 2023

Plastic replacement cartridges for Eagle glass-cartridge pens

Completely by chance a small hoard of plastic storage vials came my way that turned out to be just the right size, requiring only to be shortened by 1/4 inch. Since their wall thickness is significantly less than that of the original glass cartridges, an original cartridge nipple is too small to fit.

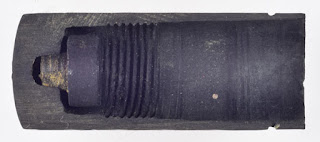

The pen above was missing its original nipple so a new one of hard rubber was made to original dimensions. As an experiment, a retaining groove was cut so an O-ring could be installed to provide a seal. While the same could be done to an original nipple, leaving it intact would be far preferable. And, as I found out after further experimentation, far easier.

Sunday, June 25, 2023

Rendell and Fairchild revelations from the R. G. Dun collection

The R.G. Dun collection of 19th-century credit reports first came to my attention years ago with the publication of Barbara Lambert's A. T. Cross monograph (Writing History, 1996). Though housed nearby at Harvard's Baker Library it was only last week that I finally made my first visit. While I had been hoping to find new insights into the relationships between early manufacturers of fountain pens and pen parts, it turned out that the collection ends a few years too early to be helpful there. Where it proved to be most informative was in the span from the 1850s through the 1870s, the heyday of the dip pen.

As I am still learning my way around the collection -- the librarians have been unfailingly welcoming and helpful -- it will be a while before there are any proper writeups. Nonetheless, there have been enough fresh discoveries that it's worth sharing a few of them now.

The first entry in the Dun records that I have found for gold pen pioneer John Rendell is from 1855. His partnership with Leroy W. Fairchild was then less than three years old. While I had previously speculated that Fairchild had apprenticed with Rendell, it appears that Fairchild hadn't come to Rendell as a penmaker at all, but rather as a salesman and bookkeeper having been previously employed in that capacity by the stationery firm of William H. Arthur & Co. While the report praises both men only Rendell is described as "a practical pen-maker", while Fairchild's business and money management skills are cited as the mainstay of the business's success.

My previous efforts to find out when the Rendell & Fairchild partnership was dissolved were not successful. The Dun records, however, put the date of dissolution at the beginning of August 1857 with Fairchild buying out Rendell for $5400, partly in cash and with six months to complete payment. Rendell was to stay on as an employee for up to three years -- though as we know, he died only eighteen months later under tragic circumstances.

Thursday, June 8, 2023

Making safety pens yet safer

A customer was recently asking about safety pen leakage. A safety with good seals should be as leakproof as any fountain pen could be. That doesn't mean, however, that it can't leave a mess quite without any leakage. One example is how ink can end up spattering in tiny droplets when the nib is extended if there happens to be a film of ink spanning the barrel opening when the pen is uncapped, like the soap solution across a bubble-blowing wand.

My customer's issue was something a bit different, though. It seems it was a matter of ink sticking to the plug inside the cap. When the cap is tightened the plug is pressed firmly against the barrel mouth, as can be seen in the photos above and below. Yet as the closeup below shows, any ink that ends up sticking to the face of the plug is going to drip into the threads once the cap is removed and set on its side. And from the cap threads it will soon enough end up on the barrel threads and thence on the writer's fingers.

Monday, May 1, 2023

Research in progress: rewriting the history of the first retracting-nib safety pens

- The Caw's safety was introduced in 1895. Ads and imprints reference patent US533942 of 2/12/1895. No one seems to have remarked that the only claim in that patent is for the nib and feed arrangement. In fact, the pen shown is a sliding-action safety of the sort described in Moore's patent of 1896!

- The key patent for a safety with a turning internal helix was Peck & O'Meara's US523234 of 7/17/1894. And in 1895 the Horton Pen Company was just getting started after having acquired Peck & O'Meara's entire manufacturing operation -- including, it would appear, their patents. How could Caw's have gotten away with such a brazen infringement? The more I think about it, the more impossible it seems. Surely F. C. Brown was a licensee, though no mention of the Peck & O'Meara patent appears in Caw's ads, catalogs, or imprints. Seeing how Brown didn't lose an opportunity to trumpet all the patents he had (on later Caw's safeties the patent imprints run almost all the way around the barrel, headed by "F. C. BROWN PATENTS") I can only surmise that the flip side of this was an aversion to acknowledging any patents other than his own. [UPDATE: Upon closer examination, I can now see how Brown might have been able to evade the Peck & O'Meara patent at least in part by using a single-slot mechanism and a separate internal sleeve to carry that slot]

- It has been claimed that Caw's bought up all the assets of the Horton Pen Company after it failed. I can find no evidence of any such failure. Horton appears in New Haven city directories all the way through 1901, after which it was acquired -- but by Frazer & Geyer, not Brown. There are plenty of retailer ads for Horton pens through 1899 at least as well as other mentions indicating production overlapping with that of Caw's for several years.

- If Caw's was a licensee of Horton, as the notes above suggest, was Horton also supplying pens or pen parts to Caw's? Caw's was already producing the Dashaway so did not necessarily need a new subcontractor. On the other hand, making the safety spirals was something new. It may be significant that the interior structure of Caw's and Horton safety barrels is different, the straight tracks being cut directly into the barrel interior for the Horton, but cut into an inserted sleeve for the Caw's.

- Whether or not Horton was doing any manufacturing for Caw's, it does appear to have been doing so for Morris W. Moore during his short-lived effort at independent pen production, prior to selling out to Cushman. The evidence for this is just one pen: the unmarked safety that I shared in a private Facebook group a while back that is virtually identical to what is shown and claimed in Moore's first 1896 patent. There are a couple of construction details that differ from the patent diagrams but which correspond to peculiarities of early Hortons, including near-interchangeable caps.

- The one patent date that appears on Caw's safeties that doesn't reference one of Brown's inventions is Sep 8, 1896 -- the date of the two Moore patents assigned in part to F. C. Brown. It is likely the second that was actually used, which claims a tapered rather than a cylindrical barrel mouth bore. This raises the question of what relationship Brown had with Moore at the time that the 1896 patent-style pen was made (which could have been as early as late 1894). Did Brown provide any sort of assistance to Moore? Or was it nothing more than Brown paying Moore for patent rights?

- It has also been claimed that Waterman acquired or licensed patents belonging to F. C. Brown for their own safeties. I can find no evidence for this, and it is noteworthy that no such patents are referenced in Waterman safety imprints where one would expect them.

- It has been claimed that Caw's patent US612013 of 1898 was for the helical retraction mechanism, and that this patent was sold to Waterman. Except that's not what the patent claims: it is solely for an improvement to such mechanisms, where the driving peg is equipped with a rolling bearing to reduce wear.

- The Nichols patent of 1903, referenced on the caps of older Wateman safety pens, doesn't seem to contain much that is novel aside from the inner cap plug closure.

- Possible missing-link or offshoot models that I don't own but would like to be able to acquire or examine: Phelps Safety; Lincoln Safety; Atlantis.

Saturday, April 29, 2023

What's in a name? The Moore Fingertip

Collectors have long wondered about the naming of the Moore Fingertip. The streamlined nib assembly echoes the aesthetics of airplanes and rockets -- so why "Fingertip" (or "Finger Tip")?

Nearly thirty years ago I completely took apart a Fingertip nib assembly, and it immediately struck me that the "fingertip" reference might well have been to the design's feed. You don't really see it from the patent drawings, so I've been waiting until I had another Fingertip apart so I could finally photograph the parts properly so viewers can judge for themselves.

A few caveats: Moore ads don't explain the Fingertip name, nor does the utility patent despite its unusually discursive descriptive text. For now this is a bit of a guess: that at some point in the design's evolution, the resemblance of the feed's narrow end to a fingertip pressing against the underside of the nib was noted and the name stuck.